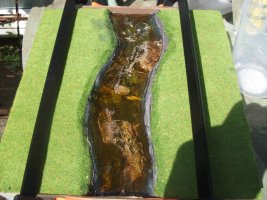

bugger.. Gonna leave this image at full size cause my close ups didn't go great but..

I think maybe it was a bit TOO hot today.. Lets see:

1) Some cracking on the paint/plaster on the sides of the River. this isn't a huge thing.. touch most of that up with some paint and some flora

2) it's a bit... yellow tinted.. Not sure why on that bit.. but fair enough for a river I guess

3) alot of air bubbles formed.. at first, this seam to start to form as it was pushing air out and the bubbles started to pop but then... yeah... not fantastic.. but.. guess I can get away with river life and maybe the odd bits of weed and stuff can hide some of it.

4) it's got cracks in it.. There are visible and clear cracks in the rivers. when putting your finger over, you can feel they are cracks..

Do I think this board is completely toasted? no.. Just not fantastic even after I put a top layer to texture it.. I'm thinking maybe putting some flora and stuff before I texture the surface so that it can be seen going a little under..

What do I personally think went wrong? It's already feeling solid to the surface.. after about 2 hours..

i) Maybe when I mixed out the amounts I screwed up. My notes and what I remember say I had 150ml Resin to 75ml hardner.. though as the jug I used doesn't (or atleast where I was looking) measure halfs, I could be slightly off but that it was about right, putting a total of 225ml of resin, no more then 250ml.. that 25ml possible extra of hardner might have created a slight problem with too much hardner.. I don't think it was as much as 25ml more but it might have been up to that..

ii) whatever Temp it is... might be just too damn hot. It says the maximum ambient temp should be 25c.. we are late spring.. I didn't quite expect it to be quite as hot as it is, but maybe its been more 30c or more.. Having got my temp meter to check right now.

Anyone else got ideas what else might have screwed it, or any ideas for.... 'improving' the look of this one?

Minor update: according to the temp meter on the window which is.. some old thing now.. it's about 40c outside.. yikes..